At CavMac, we provide a Vulcanised Rubber Lining Service. Rubber Lining is a premium form of corrosion protection for Plant and equipment in some of the most severe environments.

Index

Get A Quote

If you have any questions you are more than welcome to get in contact with us at sales@cavmac.com

Tel. +353 (0)49 555 2340

Rubber Lining

New parts can also be steel fabricated and rubber lined to the required specification. Old worn rubber coatings can be removed from the used equipment, metal parts refurbished and prepared for a new covering. We cater for both one of pieces and high-volume parts. We also offer a shot-blasting and painting Service.

We work with new and used equipment for:

• The Mining, Quarrying and Aggregates Industry,

• The Marine and Off Shore Industry,

• The Steel Industry,

• The Chemical & Pharmaceuticals Industry,

• Food and Brewing Industry,

• Power Generation Stations,

• Water and Effluent Treatment Plants

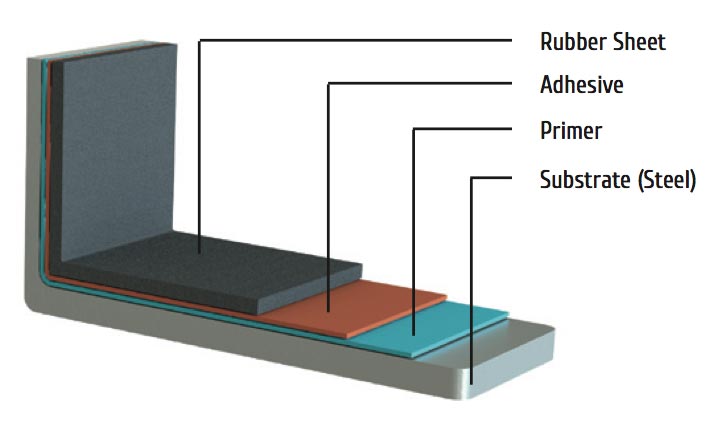

Rubber linings are cut to size and applied by hand in sheets. For irregular shapes and optimum adhesion they are applied in an un-vulcanized state and then cured using heat in an autoclave. The heat reacts with the adhesion system to create an extremely aggressive bond to the steel. Available in a wide selection of thicknessess.

RUBBER LINING SYSTEM

The Advantages of using CavMac Rubber Lining on plant and equipment is the excellent resistance to combat such conditions as:

• Abrasion & Wear

• Corrosion

• Weathering

• Vandalism

• Chemical Attack

• Acids or Alkalis

• Oils or Grease

• Sea Water

Other uses:

• Sound dampening for noise reduction

• Thermal Insulation

• Aesthetic Finish

• Electrical Insulation or Conductivity